Our advanced automated noodle production equipment allows us to deliver hygienic and delicious noodles tailored for OEM/ODM needs. In addition to our large-scale manufacturing capacity, our strict hygiene and food safety protocols give brand partners full confidence in our production process.

Fresh flour is delivered daily via dedicated trucks from the flour mill and transported through dedicated pipelines into sealed storage silos, ensuring safe tra...

We utilize an advanced German flour conveying system, featuring automatic sifting and precise weighing before delivery to the production site.

Time, temperature, and humidity are carefully controlled to allow starch and protein in the flour to absorb moisture evenly, enhancing gluten structure and impr...

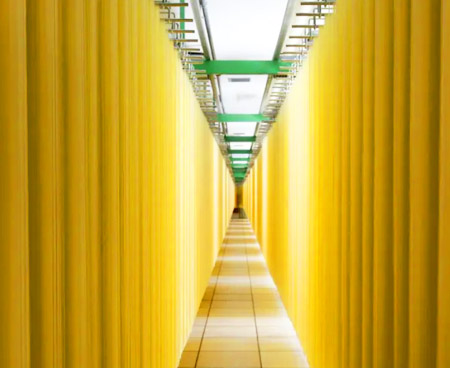

Occupying a drying length of 820 meters, the process takes approximately 8–9 hours with multi-stage temperature and humidity control to ensure optimal drying. S...

Uses controlled temperature and airflow to rapidly extract moisture without frying, improving elasticity, firmness, and shelf life of the noodles.

Features a nine-stage pressing process to evenly develop gluten, resulting in a firmer texture and better mouthfeel, while ensuring consistent high-quality outp...

Utilizes steam to pre-gelatinize noodles, enhancing texture and bite while reducing cooking time. Emphasis is placed on food safety and hygiene during productio...

Incorporates chilled brine during mixing to allow uniform hydration of starch and protein, promoting gluten development for superior dough elasticity and textur...

High-speed clean air removes dust, hair, and other particulates from garments to maintain air cleanliness in the workspace, complying with high hygiene and safe...

1

Flour is transported using dedicated trucks and delivered to our fully automated storage silos and transfer system. The entire process is completely sealed from transportation to manufacturing, effectively preventing contamination. Our facility meets high-tech factory standards and complies with strict food safety regulations.

2

Flour is automatically piped into the mixing tanks, where it is blended with ice brine. This reduces heat generation during mixing, promotes even moisture distribution, and strengthens the gluten structure, resulting in noodles with better elasticity and chewiness.

3

Two sheets of dough are combined and rolled into one, expelling air from the dough to increase its density and firmness.

4

Controlled temperature and humidity are used to allow the noodle sheets to mature, enhancing dough elasticity. The maturation process improves noodle plasticity and softness, strengthens protein bonding, and ultimately enhances the noodle’s texture and overall quality.

5

The rolled dough is fed into a cutting and waving device that shapes the noodles into a signature wavy form.

6

High-pressure steam is used to gelatinize the noodles, locking in structure and improving bite.

7

Our large-scale automated drying equipment features advanced temperature and humidity control, enabling efficient and stable drying of the noodles.

8

After drying, the noodles are cut to the desired length in preparation for final packaging.

9

Final packaging is carried out using automated systems. Each package passes through weight detection and X-ray inspection to eliminate any product that is underweight or contains foreign metal objects, thus ensuring the highest standards of quality control and safety.

1

Flour is transported using dedicated trucks and delivered to our fully automated storage silos and transfer system. The entire process is completely sealed from transportation to manufacturing, effectively preventing contamination. Our facility meets high-tech factory standards and complies with strict food safety regulations.

2

Flour is automatically piped into the mixing tanks, where it is blended with ice brine. This reduces heat generation during mixing, promotes even moisture distribution, and strengthens the gluten structure, resulting in noodles with better elasticity and chewiness.

3

Two sheets of dough are combined and rolled into one, expelling air from the dough to increase its density and firmness.

4

The key to noodle texture lies in precision rolling. At SING-LIN, dough sheets are rolled through nine stages, gradually thinning the sheet while enhancing texture and mouthfeel.

5

The rolled dough is fed into a cutting and waving device that shapes the noodles into a signature wavy form.

6

High-pressure steam is used to gelatinize the noodles, locking in structure and improving bite.

7

Our large-scale automated drying equipment features advanced temperature and humidity control, enabling efficient and stable drying of the noodles.

8

Final packaging is carried out using automated systems. Each package passes through weight detection and X-ray inspection to eliminate any product that is underweight or contains foreign metal objects, thus ensuring the highest standards of quality control and safety.