Contamination-Free Flour Delivery System

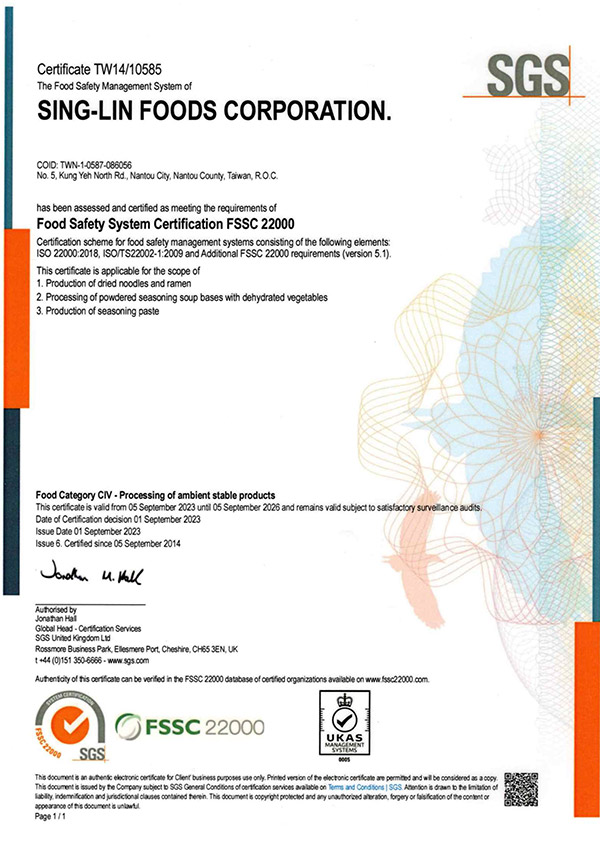

We uphold the highest standards of safety and hygiene and have earned multiple international quality certifications.

Outstanding Hygiene and Quality Control

1Dedicated trucks for flour transport.

2Automated flour silo system.

3100% resistant to fluctuations in temperature and humidity.

4Monthly equipment maintenance, cleaning, and disinfection.

5Production takes place in air-conditioned facilities with filtered air exchange systems.

6Strict disinfection procedures for all personnel and controlled entry access protocols—on par with high-tech manufacturing standards.